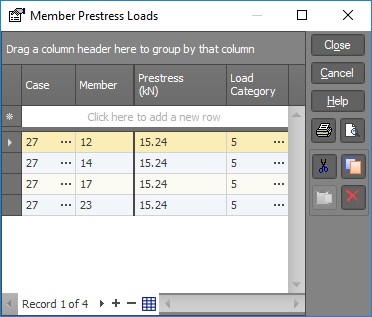

Member prestress data

A prestress can be applied to a member by specifying a tensile or compressive force. Prestress loads act over the entire length of the members on which they are applied.

It is possible to model prestress loads with equivalent thermal loads and vice-versa, however this is generally unnecessary because they can both be applied directly in SPACE GASS.

Prestress loads may be applied in any load case and may be combined with other load types within the same load case.

![]() Note that the prestress load you apply to a

member is not likely to be the final axial force in the member at the end of the analysis (unless its ends are fixed in position or don't move). This is because the axial force changes as the member stretches or compresses as its end nodes move.

If you wish to achieve a particular axial force at the end of the analysis then a trial and error process is required. This involves setting an initial prestress force, performing the analysis, checking the final axial force, adjusting the prestress

and repeating the process until the desired axial force is achieved. This is a common requirement in post-tensioned concrete applications where the tendons are jacked to a known tension.

Note that the prestress load you apply to a

member is not likely to be the final axial force in the member at the end of the analysis (unless its ends are fixed in position or don't move). This is because the axial force changes as the member stretches or compresses as its end nodes move.

If you wish to achieve a particular axial force at the end of the analysis then a trial and error process is required. This involves setting an initial prestress force, performing the analysis, checking the final axial force, adjusting the prestress

and repeating the process until the desired axial force is achieved. This is a common requirement in post-tensioned concrete applications where the tendons are jacked to a known tension.

Case

Load case to contain prestress loads.

Member

Member to be loaded.

Prestress force

The prestress force is positive for compression or negative for tension.

Load category

The load category column lets you specify which load categories the loads will go into. For more information refer to "Load categories".

![]() In some instances, you may wish to apply a prestress load to a cable member instead of specifying

a non-zero unstrained cable length. The prestress load P that is equivalent to an unstrained cable length L is given by the equation:

In some instances, you may wish to apply a prestress load to a cable member instead of specifying

a non-zero unstrained cable length. The prestress load P that is equivalent to an unstrained cable length L is given by the equation:

![]()

|

where |

D = chord length, |

|

|

A = cross sectional area, |

|

|

E = Young’s modulus of elasticity. |

See also Member prestress loads text.

See also Datasheet Input.

See also Member prestress loads.

See also Cable members.

See also View diagrams.